Charging & Discharging

Flecotec - The most Innovative Single-Use Containment Solutions

With its patented Flecotec technology, Rommelag FLEX is the only partner you need for your single-use containment requirements up to OEB 5 level.

Flecotec Product Overview

ZIP

ZIP

Maximum Flexibility with Flecotec ZIP Containment System

Pioneering flexible interfaces, we provide an end-to-end single-use containment solution adaptable to any interface size - from 2 inches to barrel size. Our patented ZIP containment technology seamlessly integrates with your existing processes as secondary containment, eliminating the need for modification or revalidation.

This unparalleled flexibility allows us to cover a complete pharmaceutical or API production up to OEB 5 level without requiring any additional technology. Moreover, our free cross-section design eliminates the "ring of concern."

QuickTric

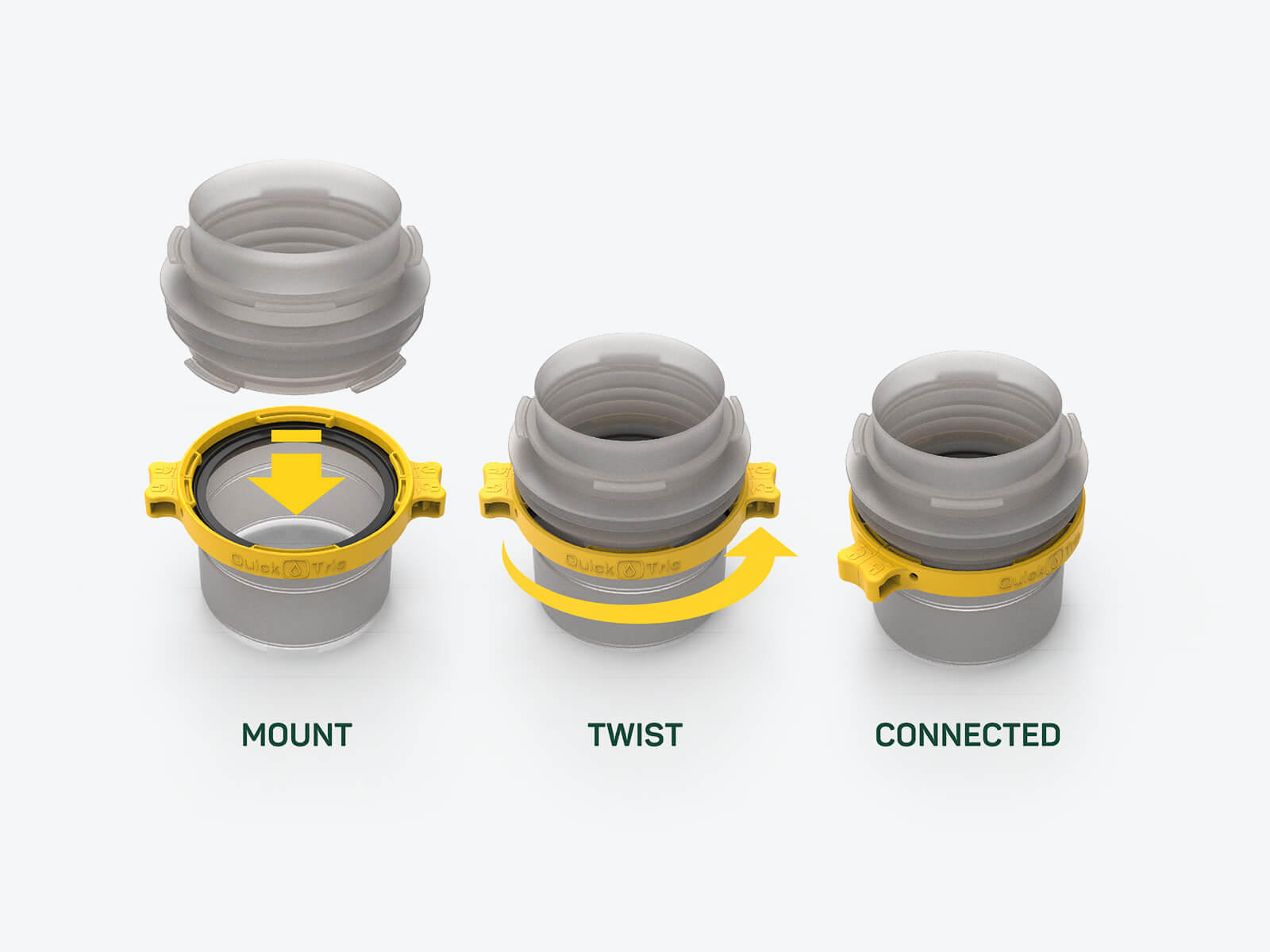

Tri-Clamp Interface Next Level - The Flecotec QuickTric

Mount, twist, and it’s connected - with the new Flecotec QuickTric, creating Tri-Clamp interfaces has never been faster or easier. Compared to a standard Tri-Clamp interface, the QuickTric is twice as fast and reduces error rates by locking the seal in place, preventing it from slipping or even falling into the processing unit.

Additionally, it offers a free cross-section for smooth material flow and ensures no seal abrasion.

Film

In-House Film Production

At Rommelag FLEX, we take pride in our state-of-the-art in-house film production capabilities. This strategic advantage allows us to offer flexible production quantities, ensuring faster and more reliable delivery times. Benefit from significant cost savings, rapid availability, and the ability to produce smaller batches—all without sacrificing quality or service.

Rommelag Group

Rommelag FLEX: Strong Division of an Unbeatable Group

The Rommelag Group is an association of nine family-owned companies specializing in specific challenges in the pharmaceutical, cosmetics and chemical industries. Our locations are in Switzerland, Germany and India. We operate sales companies in China and the USA as well as agencies in over 20 countries.

Rommelag is the umbrella brand for our products and services. It bundles the five divisions: FLEX, Engineering, CMO, Digital and Service. It all began in 1952 with film extrusion. Today, Rommelag FLEX continues to offer first-class quality and comprehensive expertise for your benefit.